Headquarters of BNP Paribas Fortis - Montagne du Parc

- Solution

- Colab

- Client

- NCBHAM & Jaspers-Eyers

- Location

- Brussels

- Type

- B2B

- Surface

- 2,000 m²

Architectural furniture at BNP? More than inviting

No fewer than 4,500 BNP Paribas Fortis employees are based at their new headquarters onMontagne du Parc in the heart of Brussels. This architectural masterpiece, designed by Baumschlager Eberle, Jaspers-Eyers and Styfhals, looks like an imposing white ship.

The building is designed to be open and to encourage interaction. This includes 2,000 m² dedicated to catering. The NCBHAM architectural firm has been awarded a development contract.

NCBHAM has come up with a range of food counters, spread over 4 floors and offering a variety of catering options: a Barista Bar, a Hot Corner, a Sweet Corner and a Fresh Corner. This will bring life to every floor and transform these spaces into a place for friendly, multi-faceted encounters

NCBHAM and PLUO, a symbiosis of skills

Renowned for their innovative vision and architectural creations that combine aesthetics, functionality and sustainability, the designers at NCBHAM needed a partner who could help them push back the boundaries of their creativity even further, based on the fusion of digital and traditional craftsmanship. PLUO has 30 years' experience in the production of made-to-measure furniture, and is an expert in both digital design and craftsmanship.

Image Gallery

Dream, yes... but try everything!

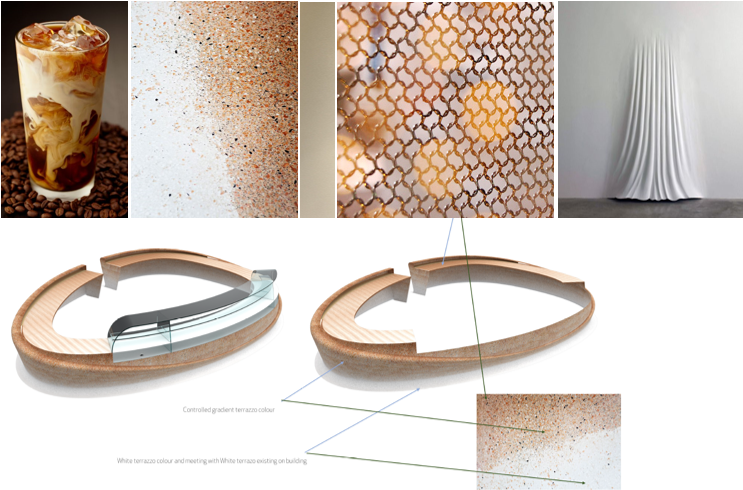

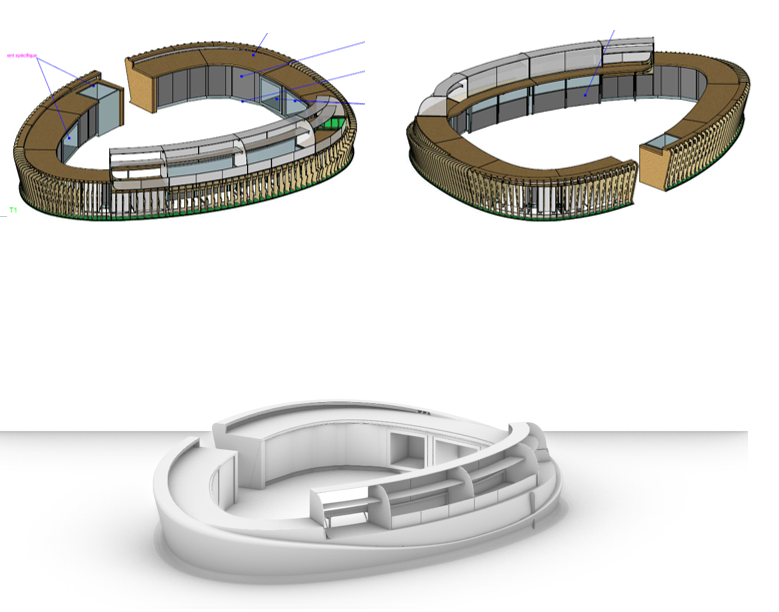

The NCBHAM and PLUO teams worked hand in hand to produce the technical study for the furniture. An essential starting point for validating ideas.

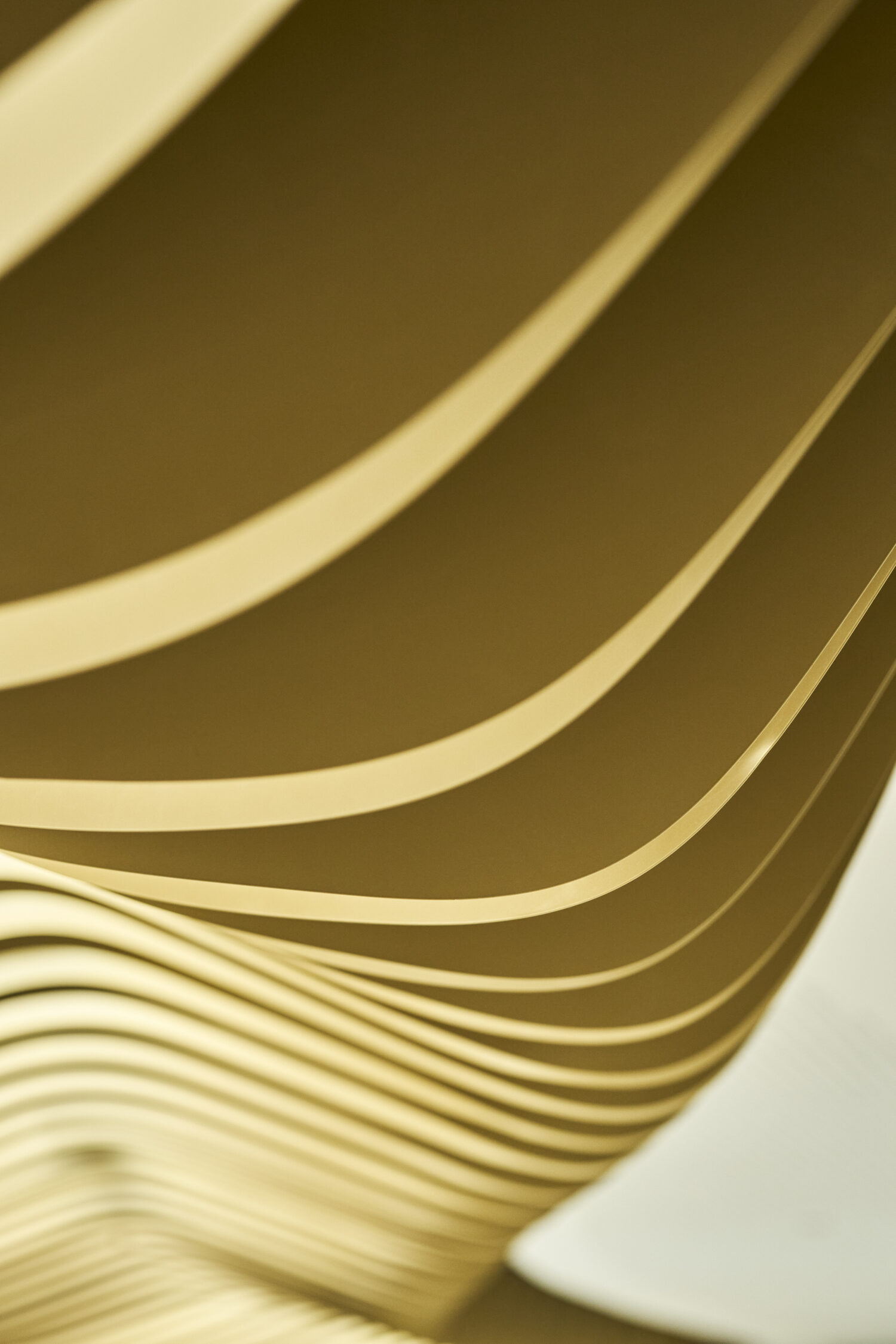

The computer design stage then enabled us to perfectly rationalise the production of the furniture and its structure (counters and ceilings). Once these calculations were complete, the furniture was ready to be shaped by our craftsmen. Make way for their creativity!

The wooden countertops were covered in Terrazzo, with fragments of coloured natural stone and marble assembled and calibrated to ensure a smooth transition of tones.

Save time and money: furniture mock-ups

As is often the case with complex furniture projects, we produced prototypes, which enabled us to ”see” the furniture in a three-dimensional environment and create a realistic representation of it.

These mock-ups also made it easier to identify and correct any errors at the very start of the process. Finally, they gave us the opportunity to test the functionality of the furniture and improve the aesthetic details.

These are all invaluable advantages for smooth communication between partners, saving time and avoiding additional costs during production

Image Gallery

Image Gallery

When craft meets digital, the entire design and construction process benefits from the best of both worlds… This harmonious marriage opens the door to infinite possibilities, inviting the creation of unique pieces that combine aesthetics, functionality and durability.